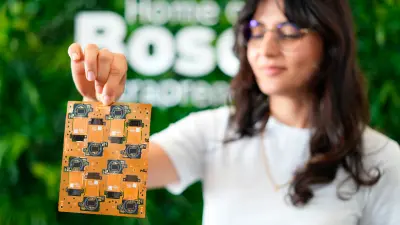

Design for manufacturing

Maximize efficiency and minimize costs with the copperdot design for manufacturing (DFM) service. Powered by Bosch’s extensive expertise, we tailor your PCB designs to meet exacting application standards.

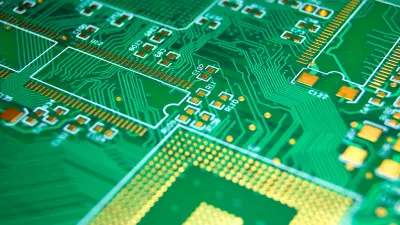

Streamlined manufacturing precision

Navigating the complex landscape of HDI PCB production demands a nuanced understanding of both design intricacies and manufacturing processes. copperdot’s DFM service integrates Bosch’s cutting-edge manufacturing techniques and in-depth industry knowledge to optimize your PCB designs for manufacturability from the very beginning.

Proactive design optimization

Our DFM service emphasizes proactive collaboration where our experts work alongside your designers and engineers from the initial stages of the PCB design process.

This approach ensures that each design is optimized not only for functionality but also for ease of manufacturing, cost efficiency, and reliability. By considering factors such as board layout, material selection, and component placement early on, we help prevent costly redesigns and production delays.

Technical expertise in HDI PCB manufacturing

The specialized nature of HDI PCBs requires precise manufacturing processes, such as advanced laser drilling for microvias, intricate sequential lamination techniques, and rigorous bonding cycles. Our DFM service provides expert guidance on these technical requirements, ensuring your designs incorporate the best practices for layer stacking, via formation, and trace routing to enhance product performance and durability.

Cost-effective material and process selection

Selecting the right materials and processes is crucial for achieving optimal results. copperdot leverages Bosch’s vast supplier network and material science expertise to recommend materials and manufacturing techniques that reduce costs without compromising quality. Our strategic advice helps you avoid over-specification and aligns your design with the most cost-effective and efficient manufacturing options available.

Quality and compliance assurance

Our comprehensive DFM approach not only streamlines the production process but also ensures that each PCB adheres to stringent quality and compliance standards. With copperdot, you gain the assurance that your PCBs are designed for high yields and low defect rates, meeting both industry-specific requirements and international standards.

Choose copperdot’s DFM service to transform the way your PCBs are designed and manufactured. With our expertise, you can accelerate time to market and achieve superior product quality, all while maintaining cost control and manufacturing efficiency.